Overview

SGB10 series non-encapsulated H-class dry-type transformers adopt the special technology of (Germany) MORA dry-type transformers, so that the products can fully meet the requirements of fireproof and waterproof and meet environmental protection. It is a suitable product for power distribution systems and is widely used in subways, ships, mines, chemical, power companies and densely populated buildings, where there are special requirements for safety and fire protection.

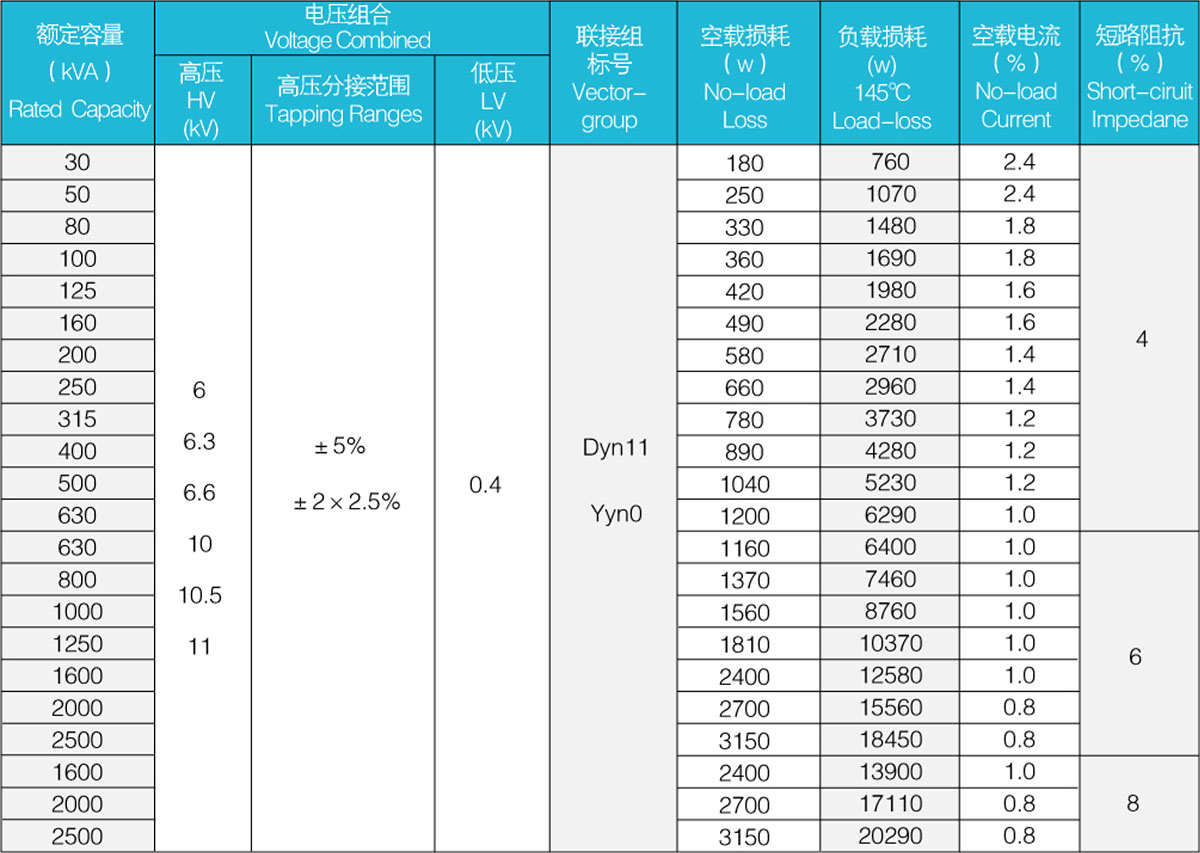

Technical parameters

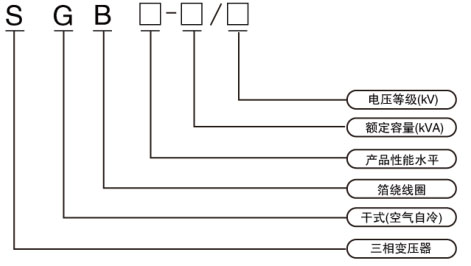

Model and meaning

PerformancePoint

PerformancePoint

1. There are several hot conditions, long thermal life, strong overload capacity, no forced air cooling under 120% long-term overload, IP45 conditions, and long-term full-load operation.

2. High safety and flame retardant performance, no smoke generated when burning at 800 °C for a long time.

3. Strong heat shock resistance (can be fully loaded at 50 ° C).

4. 100% waterproof seal, excellent water and moisture resistance.

5. The unique coil structure and strong field calculations make the product without partial discharge.

6. Low loss, energy-saving effect is obvious, compared with SC9 series dry-type music base, the no-load loss is reduced by 10% on average, and the load loss is reduced by 5%.

7. The insulation material and steel wire can be easily separated and recycled after the service life, and it does not pollute the environment.

Structural Features

1. Unique porcelain insulation structure, using MORA insulation ceramic blocks, never deformed.

2. High and low coils first use NOMEX insulation material, and have been impregnated with special grade H-class insulation by VIP vacuum press equipment. After repeated baking, high-strength insulation materials for external use. Sealed and cured at high temperatures. The high-voltage coil adopts a continuous structure with high mechanical strength and good heat dissipation conditions.

3. The core is made of high-conductivity silicon steel sheet, stepped 45° full-slant structure, winding and iron core adopt elastic fixing device, so that the pressure transformation surface has Low no-load loss and noise. The core surface is treated by a special process. The iron core is moderately clamped by the pulling screw, and the upper and lower clamp members are connected by the pull plate and fixed to the base and the winding. The winding is fixed by the elastic pad, and the buffer structure can reduce the vibration strength of the winding and reduce the noise.

4. The lead wire is fixed on the winding part of the joint in the middle of the winding, the low-voltage line terminal is the plate type conductive row, and is cold-welded.